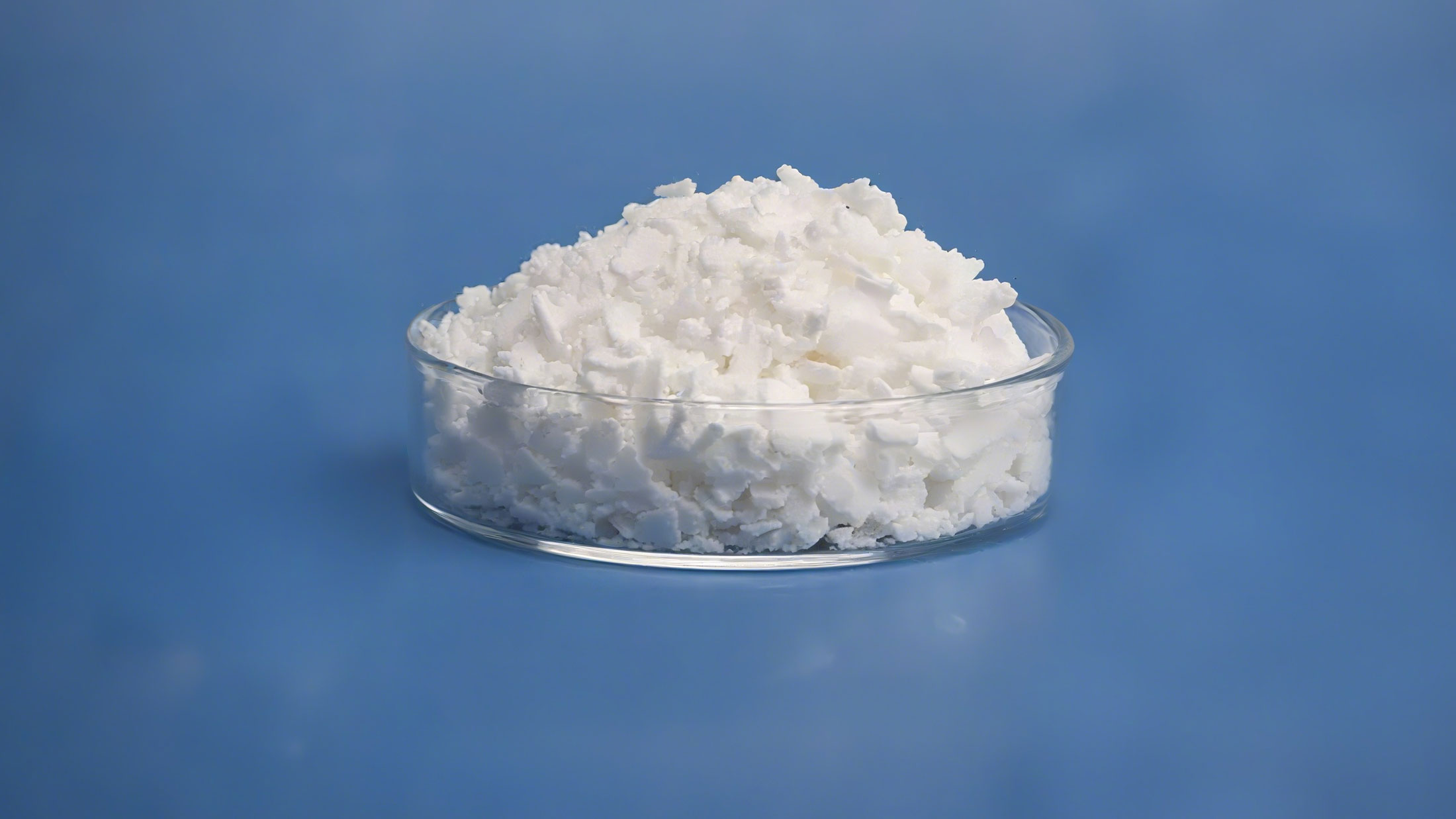

Sodium bicarbonate , as a "jack of all trades" in the chemical industry, is the basic raw material for many chemical processes. In the related processes of soda ash manufacturing, it is the core intermediate product of the Hou alkali process - using ammonia, carbon dioxide, and sodium chloride to react, first precipitate sodium bicarbonate, and then convert it into soda ash (sodium carbonate) by calcination. This "joint alkali" model greatly improves the utilization rate of raw materials. In the upstream of the chemical industry chain, it firmly supports the production foundation of soda ash and related products, just like creating a "transit station hub" for the chemical raw material system, connecting the manufacturing links of various basic chemicals.

In the environmental protection link of the manufacturing industry, sodium bicarbonate is the "environmental guardian" of flue gas desulfurization. When sodium-based dry flue gas desulfurization processes are used in steel mills, coking plants, cement plants, etc., sodium bicarbonate is used as a desulfurizer. It decomposes under heat to produce sodium carbonate, carbon dioxide and water. Sodium carbonate reacts with sulfur dioxide in the flue gas to produce salts such as sodium sulfite, realizing the removal of acidic gases. Compared with traditional desulfurizers, it has high reaction activity, stable desulfurization efficiency, and can also reduce equipment corrosion, helping enterprises to achieve environmental compliance in production and provide a "green solution" for industrial flue gas treatment.

In the field of sewage treatment, sodium bicarbonate has become a "precision regulator" for adjusting the pH of wastewater due to its weak alkalinity. For acidic industrial wastewater (such as electroplating and printing and dyeing wastewater), it can neutralize hydrogen ions , avoid strong acid corrosion of treatment equipment, and can also cooperate with other agents to promote heavy metal ion precipitation and organic matter degradation. For example, when treating copper-containing wastewater, it adjusts the pH to facilitate the precipitation of basic copper carbonate, assist in purifying water quality, and play a key role in the process of "clearing" industrial wastewater.

In the rubber industry, sodium bicarbonate is a foaming "magic agent". In the production of rubber and sponge, it is combined with alum and pore-forming agent to release carbon dioxide gas when heated, so that the rubber forms a uniform microporous structure when vulcanized, just like "blowing small bubbles" inside the rubber, improving the elasticity and flexibility of the rubber, and making the rubber products lighter and more durable. From daily rubber soles to industrial sealing rubber, it has helped to "transform" and endow the material with unique physical properties.

In the printing and dyeing industry, sodium bicarbonate is a dyeing "stabilizer". As a color fixative and acid-base buffer for dyeing and printing, it can maintain the weak alkaline environment of the dye bath, allowing the dye to better adhere to the fabric and prevent color flowers and color differences. In the post-processing of fabric dyeing and finishing, it is used to adjust the pH, which can improve the color brightness and fastness, so that the "appearance" of the printed and dyed fabric is online, and in the transformation of textiles from "blank" to "color clothes", it silently guards the color stability.

In the metallurgical industry, sodium bicarbonate is the "fluxing partner" for casting. When casting steel ingots, it acts as a flux to reduce the melting point of slag, improve the fluidity of slag, separate molten steel from impurities more thoroughly, and improve the purity of steel ingots. It is like equipping a metallurgical furnace with a "scavenger", helping to produce high-quality steel and provide high-quality raw materials for subsequent manufacturing industries.

In the machinery industry, sodium bicarbonate is a "molding assistant" for casting sand molds. In the steel casting (sand casting) process, adding it can optimize the permeability and disintegration of the sand mold, making the sand mold easy to break and clean after the molten steel is cast, and it can also reduce the pores and sand inclusion defects of the castings, improve the yield of castings, and lay a solid quality foundation for the "birth" process of mechanical parts, making precision machinery manufacturing smoother.

With these "key roles" in the manufacturing and chemical industries, sodium bicarbonate is fully embedded in the industrial production context from basic raw material supply to environmental protection management, from material modification to special process support, and has become an "invisible cornerstone" to promote industrial operation, innovation and upgrading, and continuously release the diversified value of chemical products.

18 years experience

18 years experience 6000+ m2 factory area

6000+ m2 factory area 300+ employees

300+ employees 60+ customer's countries

60+ customer's countries